Cikakken Amfani da Tsarin bushewar Zafin Sharar gida

Cikakken Amfani da Tsarin bushewar Zafin Sharar gida

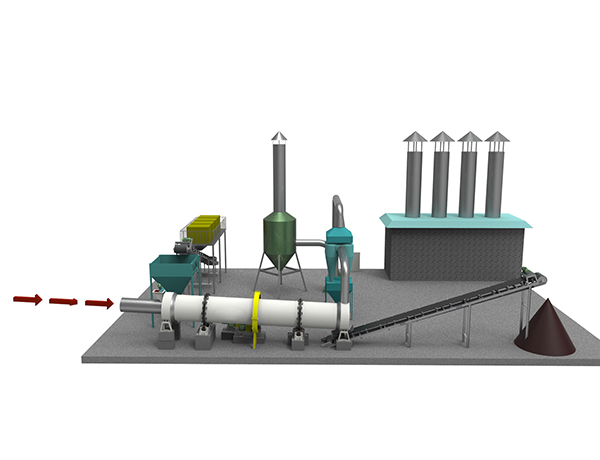

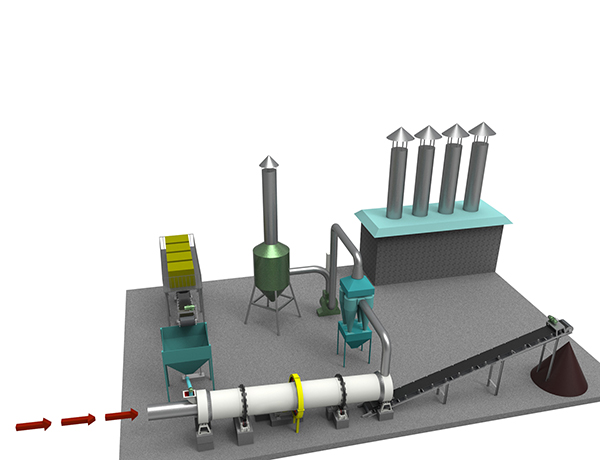

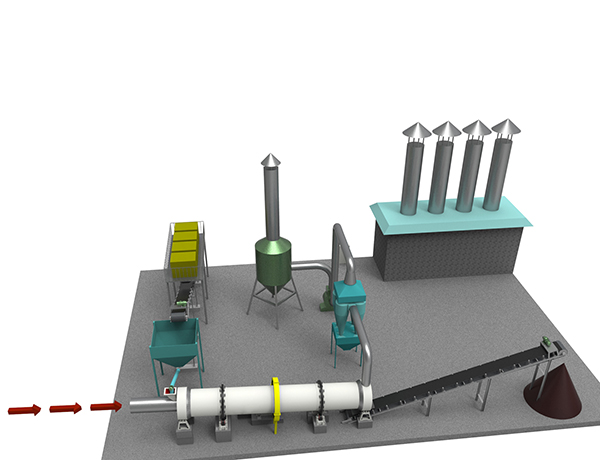

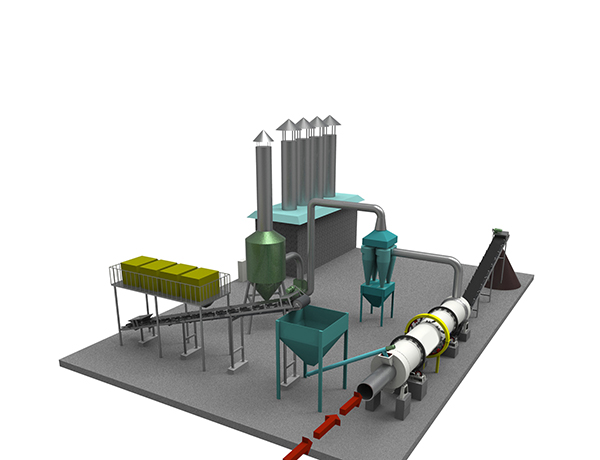

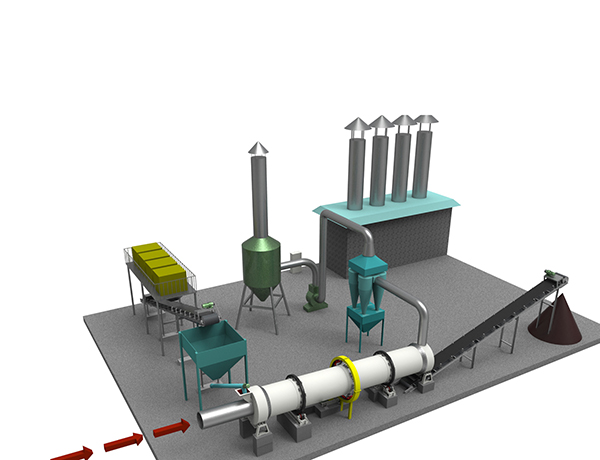

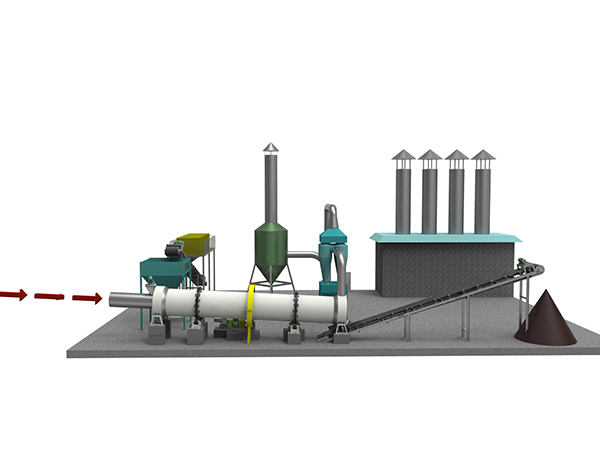

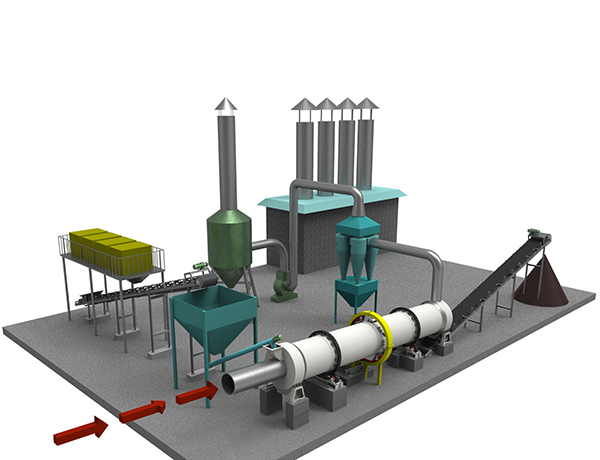

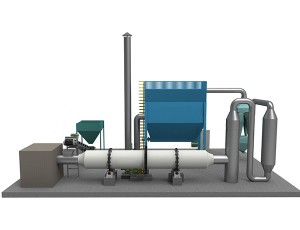

Tsarin Tsari

Za'a iya tsara makircin don ƙara yawan amfani da makamashin thermal na tsarin kamar kowane abu daban-daban, yanayin zafi mai ɓata da kuma zubar da zafi.

Cases 1: 200T/D Aikin Gudanar da Sludge na ɗaya daga cikin Kamfanonin Petrochemical na Dalian, da kwararar ƙura: 750000 Nm³/h;yawan zafin jiki: 135 ℃;Tsarin mu shine yin amfani da nau'ikan bushewa na VS 4 x 32m guda uku, waɗanda aka sanya su cikin samarwa.

Case 2: 4T / D Sludge Processing Project na ɗaya daga cikin masana'antun rini na Shanghai, kwararar ruwa: 10000Nm³ / h, yawan zafin jiki: 180 ℃;Ƙirar mu ita ce amfani da na'urar bushewa ta VS 2 x 5m, wanda aka sanya shi cikin samarwa.

Amfanin Tsarin

1. Yin amfani da zafi na sharar gida, ceton makamashi da kare muhalli;

2. Babu amfani da man fetur, ƙananan amfani da wutar lantarki, ana iya amfani da tsarin cire ƙura na asali don adana zuba jari;

3. Samun albarkatun kasa a cikin gida, ƙarin ƙasa ba a buƙatar;

4. Babban matakin sarrafa kansa, ceton aiki;

5. Ana iya daidaita lokacin bushewa, kuma ana iya sarrafa abun cikin ruwa bayan bushewa.

Ma'aunin Fasaha

| Samfura | Diamita na Silinda (mm) | Tsawon Silinda (mm) | Girman Silinda (m3) | Gudun juyi na Silinda (r/min) | Ƙarfi (kW) | Nauyi(t) |

| VS 0.6x5.8 | 600 | 5800 | 1.7 | 1-8 | 3 | 2.9 |

| VS 0.8x8 | 800 | 8000 | 4 | 1-8 | 4 | 3.5 |

| VS 1x10 | 1000 | 10000 | 7.9 | 1-8 | 5.5 | 6.8 |

| VS 1.2x5.8 | 1200 | 5800 | 6.8 | 1-6 | 5.5 | 6.7 |

| VS 1.2x8 | 1200 | 8000 | 9 | 1-6 | 5.5 | 8.5 |

| VS 1.2x10 | 1200 | 10000 | 11 | 1-6 | 7.5 | 10.7 |

| VS 1.2x11.8 | 1200 | 11800 | 13 | 1-6 | 7.5 | 12.3 |

| VS 1.5x8 | 1500 | 8000 | 14 | 1-5 | 11 | 14.8 |

| VS 1.5x10 | 1500 | 10000 | 17.7 | 1-5 | 11 | 16 |

| VS 1.5x11.8 | 1500 | 11800 | 21 | 1-5 | 15 | 17.5 |

| VS 1.5x15 | 1500 | 15000 | 26.5 | 1-5 | 15 | 19.2 |

| VS 1.8x10 | 1800 | 10000 | 25.5 | 1-5 | 15 | 18.1 |

| VS 1.8x11.8 | 1800 | 11800 | 30 | 1-5 | 18.5 | 20.7 |

| VS 1.8x15 | 1800 | 15000 | 38 | 1-5 | 18.5 | 26.3 |

| VS 1.8x18 | 1800 | 18000 | 45.8 | 1-5 | 22 | 31.2 |

| VS 2x11.8 | 2000 | 11800 | 37 | 1-4 | 18.5 | 28.2 |

| VS 2x15 | 2000 | 15000 | 47 | 1-4 | 22 | 33.2 |

| VS 2x18 | 2000 | 18000 | 56.5 | 1-4 | 22 | 39.7 |

| VS 2x20 | 2000 | 20000 | 62.8 | 1-4 | 22 | 44.9 |

| VS 2.2x11.8 | 2200 | 11800 | 44.8 | 1-4 | 22 | 30.5 |

| VS 2.2x15 | 2200 | 15000 | 53 | 1-4 | 30 | 36.2 |

| VS 2.2x18 | 2200 | 18000 | 68 | 1-4 | 30 | 43.3 |

| VS 2.2x20 | 2200 | 20000 | 76 | 1-4 | 30 | 48.8 |

| VS 2.4x15 | 2400 | 15000 | 68 | 1-4 | 30 | 43.7 |

| VS 2.4x18 | 2400 | 18000 | 81 | 1-4 | 37 | 53 |

| VS 2.4x20 | 2400 | 20000 | 91 | 1-4 | 37 | 60.5 |

| VS 2.4x23.6 | 2400 | 23600 | 109 | 1-4 | 45 | 69.8 |

| VS 2.8x18 | 2800 | 18000 | 111 | 1-3 | 45 | 62 |

| VS 2.8x20 | 2800 | 20000 | 123 | 1-3 | 55 | 65 |

| VS 2.8x23.6 | 2800 | 23600 | 148 | 1-3 | 55 | 70 |

| VS 2.8x28 | 2800 | 28000 | 172 | 1-3 | 75 | 75 |

| VS 3x20 | 3000 | 20000 | 14 | 1-3 | 55 | 75 |

| VS 3x23.6 | 3000 | 23600 | 170 | 1-3 | 75 | 85 |

| VS 3x28 | 3000 | 28000 | 198 | 1-3 | 90 | 91 |

| VS 3.2x23.6 | 3200 | 23600 | 193 | 1-3 | 90 | 112 |

| VS 3.2x32 | 3200 | 32000 | 257 | 1-3 | 110 | 129 |

| VS 3.6x36 | 3600 | 36000 | 366 | 1-3 | 132 | 164 |

| VS 3.8x36 | 3800 | 36000 | 408 | 1-3 | 160 | 187 |

| VS 4x36 | 4000 | 36000 | 452 | 1-3 | 160 | 195 |